-

Aerospace Aluminium Alloys

-

Aircraft Aluminum Plate

-

Aircraft Aluminum Sheet

-

2024 T351 Aluminum Plate

-

2024 T851 Aluminum Plate

-

2124 T851 Aluminum Plate

-

2219 T851 Aluminum Plate

-

6061 T651 Aluminum Plate

-

6082 Aluminum Plate

-

7050 T7451 Aluminum Plate

-

7050 T7651

-

7075 T651 Aluminum Plate

-

7075 T7351 Aluminum Plate

-

Aluminium 7175 T7351

-

Aerospace Aluminium Processing

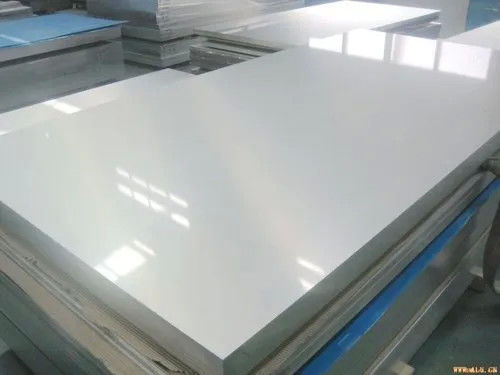

10mm-150mm 7075 T7351 Aluminum Plate Used In Aircraft Structures Rustproof

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Max Width | 2500mm-3500mm | Elongation | 5-7% |

|---|---|---|---|

| Hardness | >130HB | Heat Treatment | T7351 |

| Material | 7075 T7351 Aluminum Plate | Max Length | 6500mm-20000mm |

| Surface Treatment | Mill Finish, Anodized, Brushed, Sand Blasted, Powder Coated | Thickness | 10mm-150mm |

| High Light | 150mm 7075 t7351 aluminum plate,10mm 7075 aircraft aluminum,10mm 7075 t7351 aluminum plate |

||

Product Description:

7075 T7351 Aluminum Plate is specially designed for the aviation industry. It is a high-strength alloy with a melting point of 570℃ and a hardness of over 130HB. It has a maximum length of 6500mm-20000mm, a maximum width of 2500mm-3500mm, and a thickness of 10mm-150mm. This aviation aluminum plate 7075 T7351 has excellent mechanical properties and is widely used in aircraft structures, rivets, missile components, aircraft engine parts, etc. Its superior strength and light weight make it an ideal choice for aircraft structural components. 7075 T7351 Aluminum Plate also has excellent corrosion resistance and is widely used in cryogenic applications and harsh environments. It is an ideal choice for aerospace and military applications.

Features:

- Product Name: 7075 T7351 Aluminum Plate

- Thickness: 10mm-150mm

- Yield Strength: 340-390Mpa

- Max Width: 2500mm-3500mm

- Hardness: >130HB

- Elongation: 5-7%

- Keywords: aviation aluminum plate 7075 T7351, 7075 t7351 plate, aviation aluminum plate 7075 T7351 10mm-150mm, 7075 T7351 aluminum plate

Technical Parameters:

| Parameter | Value |

|---|---|

| Material | Aeroplane Aluminium Alloy 7075 T7351 |

| Max Length | 6500mm-20000mm |

| Max Width | 2500mm-3500mm |

| Hardness | >130HB |

| Yield Strength | 340-390Mpa |

| Tensile Strength | 430-475Mpa |

| Elongation | 5-7% |

| Surface Treatment | Mill Finish, Anodized, Brushed, Sand Blasted, Powder Coated |

| Density | 2810kg/m3 |

| Heat Treatment | T7351 |

| Melting Point | 570℃ |

Applications:

7075 T7351 Aluminum Plate from leading brand Hengtai aerospace is widely used in aviation and aerospace industry. Its hardness can reach up to >130HB, and it can be made into maximum length 6500mm-20000mm, maximum width 2500mm-3500mm and thickness 10mm-150mm. It's mill finish, anodized, brushed, sand blasted, and powder coated surface treatment makes it suitable for various applications. The 7075 T7351 Aluminum Plate is particularly suitable for aircraft frame and fuselage, aerospace structures, aviation aluminum plate 7075 T7351, aerospace aluminum plate 7075 T7351 and other related aviation and aerospace components.

Customization:

We provide custom-made 7075 T7351 aluminum plate, which is an aeroplane aluminium alloy 7075 T7351 plate, for specific applications. Our 7075 t7351 plate can have a maximum length of 6500mm-20000mm and a density of 2810kg/m3. The elongation and tensile strength of this product is 5-7% and 430-475Mpa respectively. The heat treatment of this product is T7351.

Support and Services:

We offer technical support and after-sales service for our 7075 T7351 Aluminum Plate. Our technical experts are available to help you determine the best product for your application and provide assistance in installation and maintenance.

We provide a comprehensive customer service including:

- Expert advice and guidance

- Technical support and troubleshooting

- Product installation and maintenance

- Product substitution and customization

We are committed to providing the highest quality products and services to our customers. If you have any questions or concerns about your 7075 T7351 Aluminum Plate, please don’t hesitate to contact us.