-

Aerospace Aluminium Alloys

-

Aircraft Aluminum Plate

-

Aircraft Aluminum Sheet

-

2024 T351 Aluminum Plate

-

2024 T851 Aluminum Plate

-

2124 T851 Aluminum Plate

-

2219 T851 Aluminum Plate

-

6061 T651 Aluminum Plate

-

6082 Aluminum Plate

-

7050 T7451 Aluminum Plate

-

7050 T7651

-

7075 T651 Aluminum Plate

-

7075 T7351 Aluminum Plate

-

Aluminium 7175 T7351

-

Aerospace Aluminium Processing

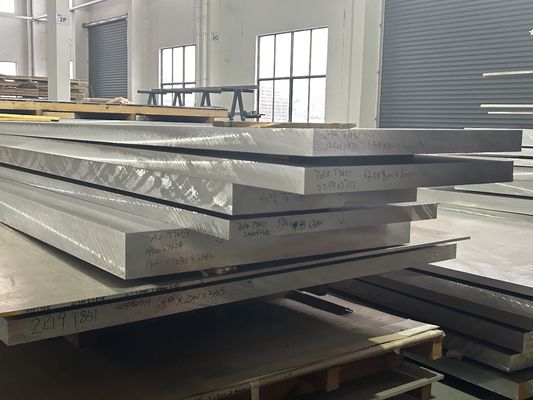

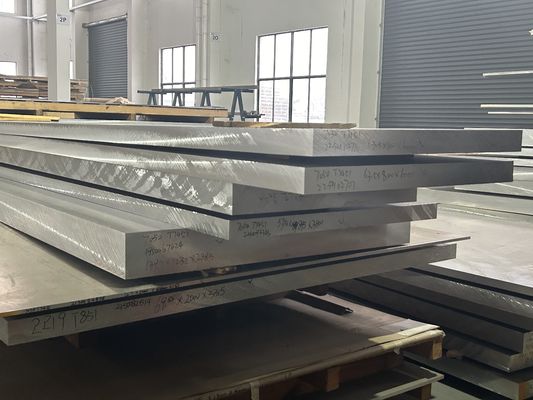

Reliable Aviation Industry 7050 T7451 Aluminum Plate Rust Prevention

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Max Length | 6500-20000mm | Tensile Strength | 430-475 MPa |

|---|---|---|---|

| Product Name | 7050 T7451 Aluminum Plate | Alloy | 7050 |

| Melting Point | 566.2℃ | Heat Treatment | T7451 |

| Elongation | 5-7% | Yield Strength | 340-390 MPa |

| Highlight | aviation industry 7050 t7451 aluminum plate,7050 t7451 aluminum plate rust prevention,aviation industry 7050 t7451 plate |

||

Product Description:

The 7050 T7451 aluminum plate is an aircraft aluminum panel which is widely used in the aviation industry. It is made from a special alloy of aluminum with superior mechanical properties, including a melting point of 566.2℃, a hardness of over 130HB, and an elongation rate of 5-7%. It is available in thicknesses of 10-150mm and in lengths of 6500-20000mm, making it the perfect choice for aircraft components. This 7050 T7451 airplane aluminum sheet is the ideal material for making aircraft parts due to its superior strength and durability. Its unique properties make it the perfect material for aircraft components and other mechanical parts.

Features:

- Product Name: 7050 T7451 Aluminum Plate

- Yield Strength: 340-390 MPa

- Melting Point: 566.2℃

- Alloy: 7050

- Thickness: 10-150mm

- Tensile Strength: 430-475 MPa

- Highly suitable for 7050 T7451 airplane aluminum sheets and 7050 T7451 aviation aluminum plate

Technical Parameters:

| Property | Value |

|---|---|

| Melting Point | 566.2℃ |

| Max Width | 2500-3500mm |

| Material | Aluminum |

| Surface Treatment | Mill Finish |

| Hardness | >130HB |

| Alloy | 7050 |

| Max Length | 6500-20000mm |

| Heat Treatment | T7451 |

| Elongation | 5-7% |

| Temper | T7451 |

Applications:

Hengtai aerospace's 7050 T7451 Aluminum Plate is an ideal material for airplane aluminum sheets and aircraft aluminum panels. It has a thickness of 10-150mm, a heat treatment of T7451, an elongation of 5-7%, a melting point of 566.2℃ and a maximum length of 6500-20000mm. Its features make it a great choice for airplanes and other aircraft applications. It has excellent corrosion resistance, high strength, and good thermal conductivity, making it suitable for various aerospace applications. It is also lightweight and cost-effective, making it ideal for a variety of applications. It is an ideal material for aircraft manufacture and maintenance, and its excellent performance ensures that it can withstand extreme temperatures and pressures. Additionally, its excellent formability makes it suitable for forming complex shapes. Therefore, 7050 T7451 aluminum plate is an ideal material for airplane aluminum sheets and aircraft aluminum panels.

Customization:

- Brand Name: Hengtai Aerospace

- Model Number: 7050 T7451

- Place of Origin: China

- Elongation: 5-7%

- Max Width: 2500-3500mm

- Melting Point: 566.2℃

- Max Length: 6500-20000mm

- Density: 2810kg/m³

Our 7050 T7451 Aluminum Plate is the ideal choice for mechanical and aerospace applications due to its superior strength and elongation. It is produced by the renowned China-based Hengtai Aerospace brand, and is available in max widths of 2500-3500mm and max lengths of 6500-20000mm. It boasts a melting point of 566.2℃ and a density of 2810kg/m³. Get the superior quality 7050 T7451 Plate for your mechanical and aerospace applications today!